- You are:

- Products

- Product

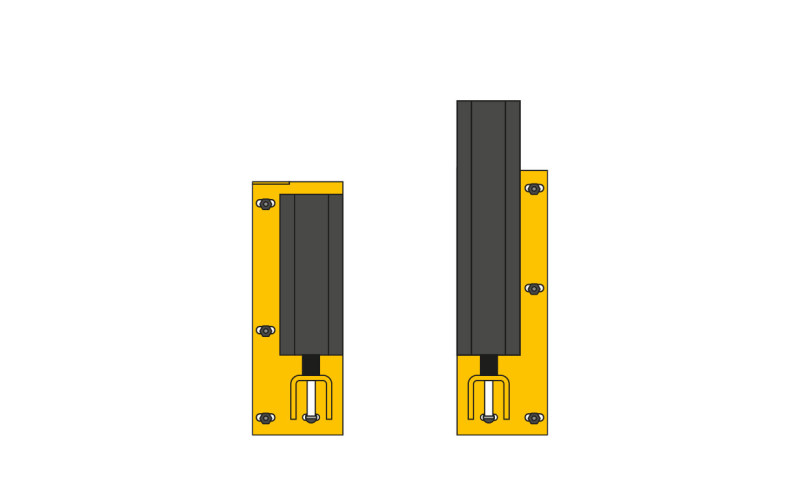

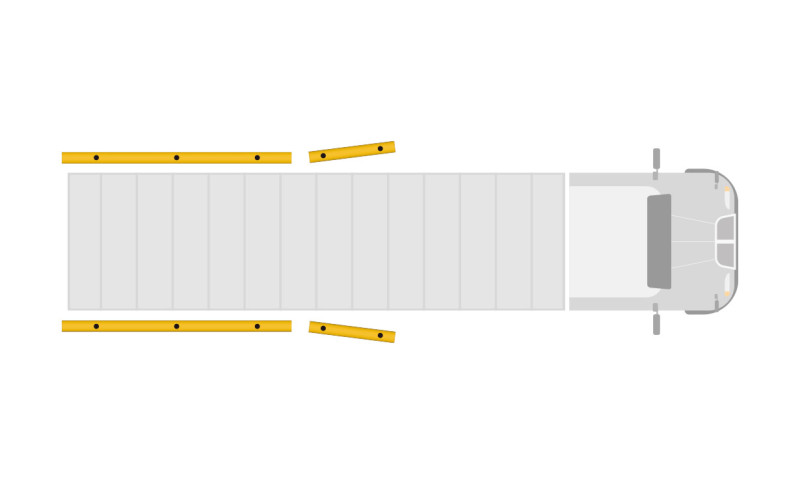

Kerb Barriers or Kickrails

Protection of employees and property from all types of handling equipment.

Kerb Barriers or Kickrails are designed for low-level impacts, especially against froklifts forks. Kerb barriers are installed to protect mainly straight lines: wall protection, rack end protection, column protection, machinery protection, loading dock protection, door protection, etc. Guardrails are usually applied to protect against material handling equipment when crashing at 90° degrees angle. To understand which guardrail model suits best the needs, it starts from assessing the Impact Safety Risk:

- Type of material handling equipment moving around: vehicle model & weight (Kg)

- Average speed at which the material handling equipment runs: km/h

- Possible angle of impact at which a material handling equipment can crash: 15°, 30°, 45° or 90°

The mix of this data helps our Safety Consultant to advise about the best kerb barrier model and its applications. Contact us for more on-line information or free on-site consultancy.

Technical Specs

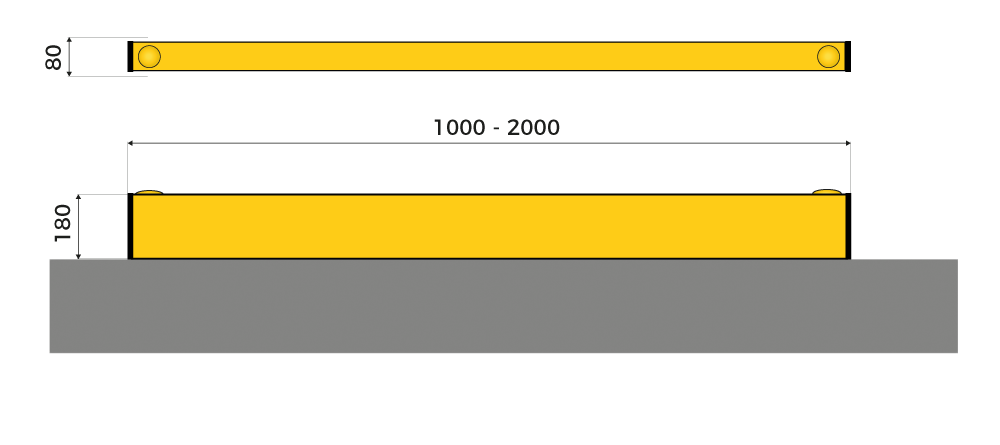

| Depth mm |

Height H - mm |

Length L - mm |

Resistance joules |

|---|---|---|---|

| 80 | 180 | 1000-2000 | 7 500 |

Advantages

HIGH HYGIENE LEVEL, EASY, QUICK AND INEXPENSIVE MAINTENANCE, NO RUSTING AND PAINTING, COST SAVINGS

Safety, Hygiene, Visibility, Modularity

Impact Energy Calculator

(please fill in the details for calculation)

Impact energy result - Joules

Precisely What You Need

Call our Safety Consultant and receive a free, no-commitment Safety Assessment tailored to your needs.

Tel.: +39 347 46 74 056 / E-mail: info@bambarrier.com

Technology

FLEXAFE™

Cutting-Edge Polymer material, designed specifically to absorb high-level impacts in a very small space. It is food-safe, doesn't break or flake, and 100% recyclable.

FOOD SAFE

Resistance to Ultra-Violate Light DIN-EN-ISO 8777-8 Blue Scale

100% recyclable

Temperature Range -40° to +50°

Compliant Crash Testing

We test our products in compliance with the industry‘s World-class standards: PAS13:2017

and UNI 11886.

- We measure barriers resistance in „Joules“ according to the following formula:

Kinetic Energy = 1/2*m*v² | M= Mass (Kg) and V = Velocity (Km/h) - We make sure test only on real floor: armed concrete; we don‘t test on metal platforms.

- We make sure vehicle impact takes place at the worst-scenario angle: 90°.

Finally, Bambarrier Bollard is certified compliant when:

- It stops the crashing vehicle safely without breaking itself and without breaking the floor.

- It can be hit repeatedly without getting loose and without breaking the floor.

- When after an impact, it occupies a very small space on the floor.