- You are:

- Products

- Product

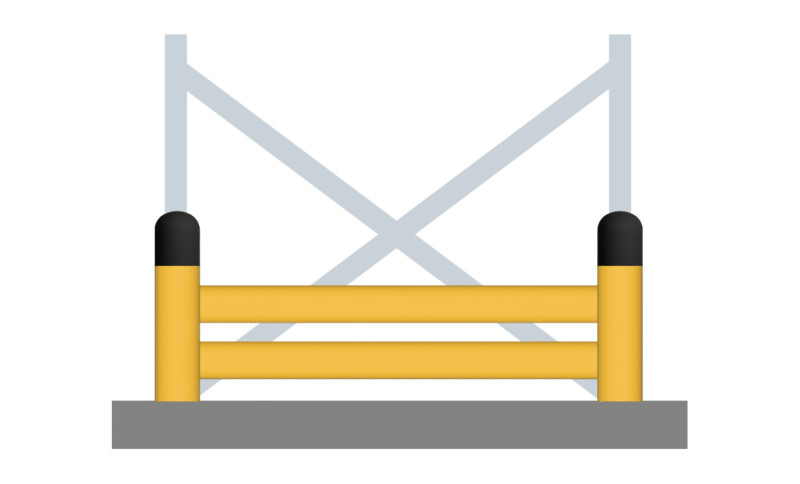

Dock Lifting Barriers

Dock Lifting Barrier is designed to protect ramps from unintended vehicle movement. This sturdy barrier effectively absorbs impacts, especially in the event of a collision with a vehicle. It features a manually operated lifting mechanism, allowing for quick and easy use. Thanks to its flexible design, it reliably safeguards gates, walls, and loading ramps.

Technical Specs

Bollards

| Diameter D - mm |

Height H - mm |

Resistance joules |

Anchoring Pullout kN |

Total Floor Space mm |

IP Grade | Flame Extinguishing Rate |

|---|---|---|---|---|---|---|

| 120 | 450 | 16 850 | 580 | 317 | 59 | UL94: HB |

| 140 | 450 | 23 950 | 580 | 265 | 59 | UL94: HB |

Lifting Guards

| Diameter D - mm |

Length L - mm |

Resistance joules |

IP Grade | Flame Extinguishing Rate |

|---|---|---|---|---|

| 125 | 2000-6000 | 23 250 | 59 | UL94: HB |

Customized solution and colours upon request

Impact Energy Calculator

(please fill in the details for calculation)

Impact energy result - Joules

Precisely What You Need

Call our Safety Consultant and receive a free, no-commitment Safety Assessment tailored to your needs.

Tel.: +39 347 46 74 056 / E-mail: info@bambarrier.com

Technology

FLEXAFE™

Cutting-Edge Polymer material, designed specifically to absorb high-level impacts in a very small space. It is food-safe, doesn't break or flake, and 100% recyclable.

FOOD SAFE

Resistance to Ultra-Violate Light DIN-EN-ISO 8777-8 Blue Scale

100% recyclable

Temperature Range -40° to +50°

ROOTLOCK®

World‘s most advanced and safe Anchorage System. It helps the floor to absorb violent and repeat vehicles impacts without damaging the floor.

Cutting-edge Anchorage System Design

Anti-Shrinkage Cement

Applications

Compliant Crash Testing

We test our products in compliance with the industry‘s World-class standards: PAS13:2017

and UNI 11886.

- We measure barriers resistance in „Joules“ according to the following formula:

Kinetic Energy = 1/2*m*v² | M= Mass (Kg) and V = Velocity (Km/h) - We make sure test only on real floor: armed concrete; we don‘t test on metal platforms.

- We make sure vehicle impact takes place at the worst-scenario angle: 90°.

Finally, Bambarrier Bollard is certified compliant when:

- It stops the crashing vehicle safely without breaking itself and without breaking the floor.

- It can be hit repeatedly without getting loose and without breaking the floor.

- When after an impact, it occupies a very small space on the floor.