Kerb Barriers or Kickrails

Protection of employees and property from all types of handling equipment.

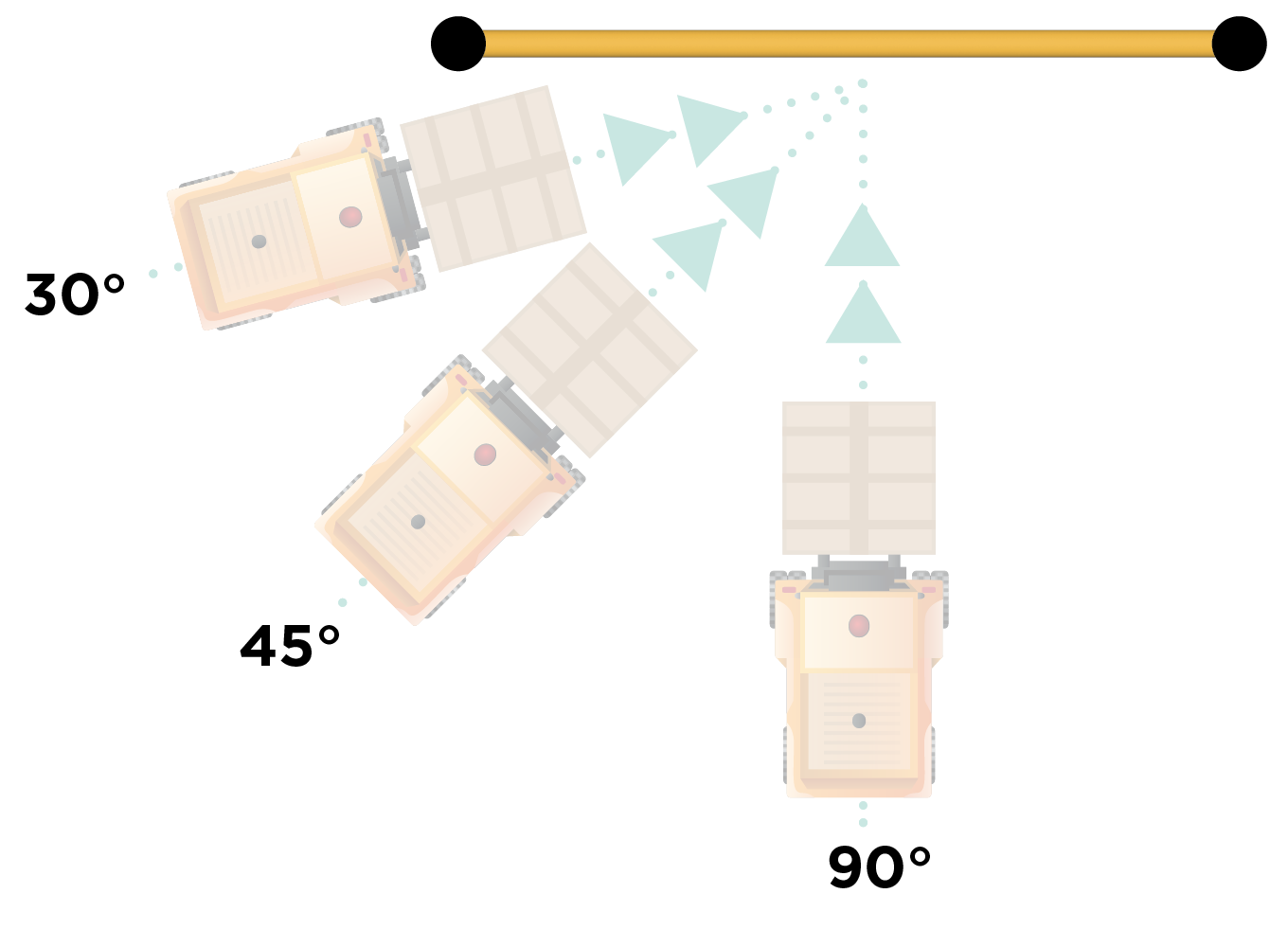

Kerb Barriers or Kickrails are designed for low-level impacts, especially against froklifts forks. Kerb barriers are installed to protect mainly straight lines: wall protection, rack end protection, column protection, machinery protection, loading dock protection, door protection, etc. Guardrails are usually applied to protect against material handling equipment when crashing at 90° degrees angle. To understand which guardrail model suits best the needs, it starts from assessing the Impact Safety Risk:

- Type of material handling equipment moving around: vehicle model & weight (Kg)

- Average speed at which the material handling equipment runs: km/h

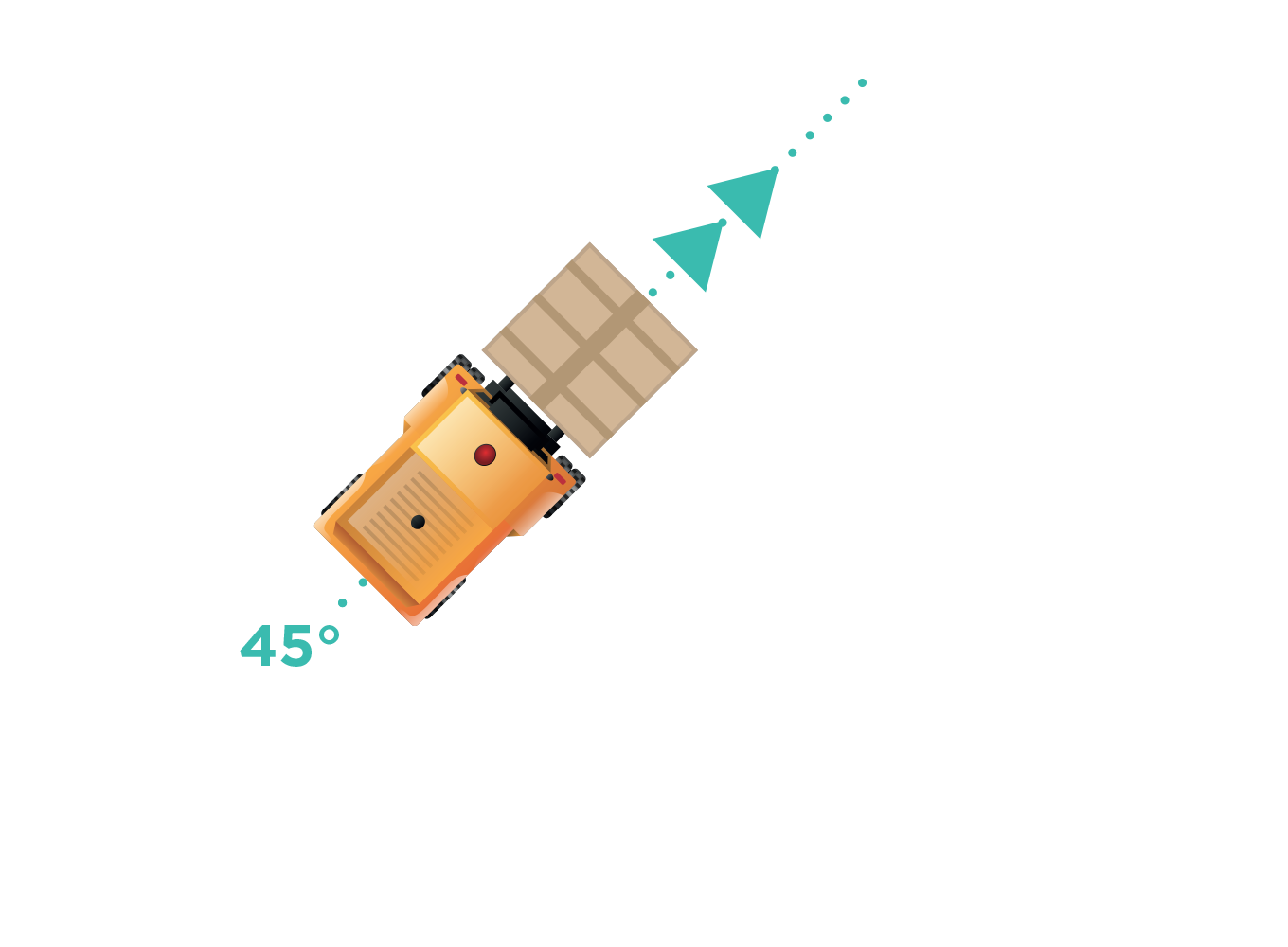

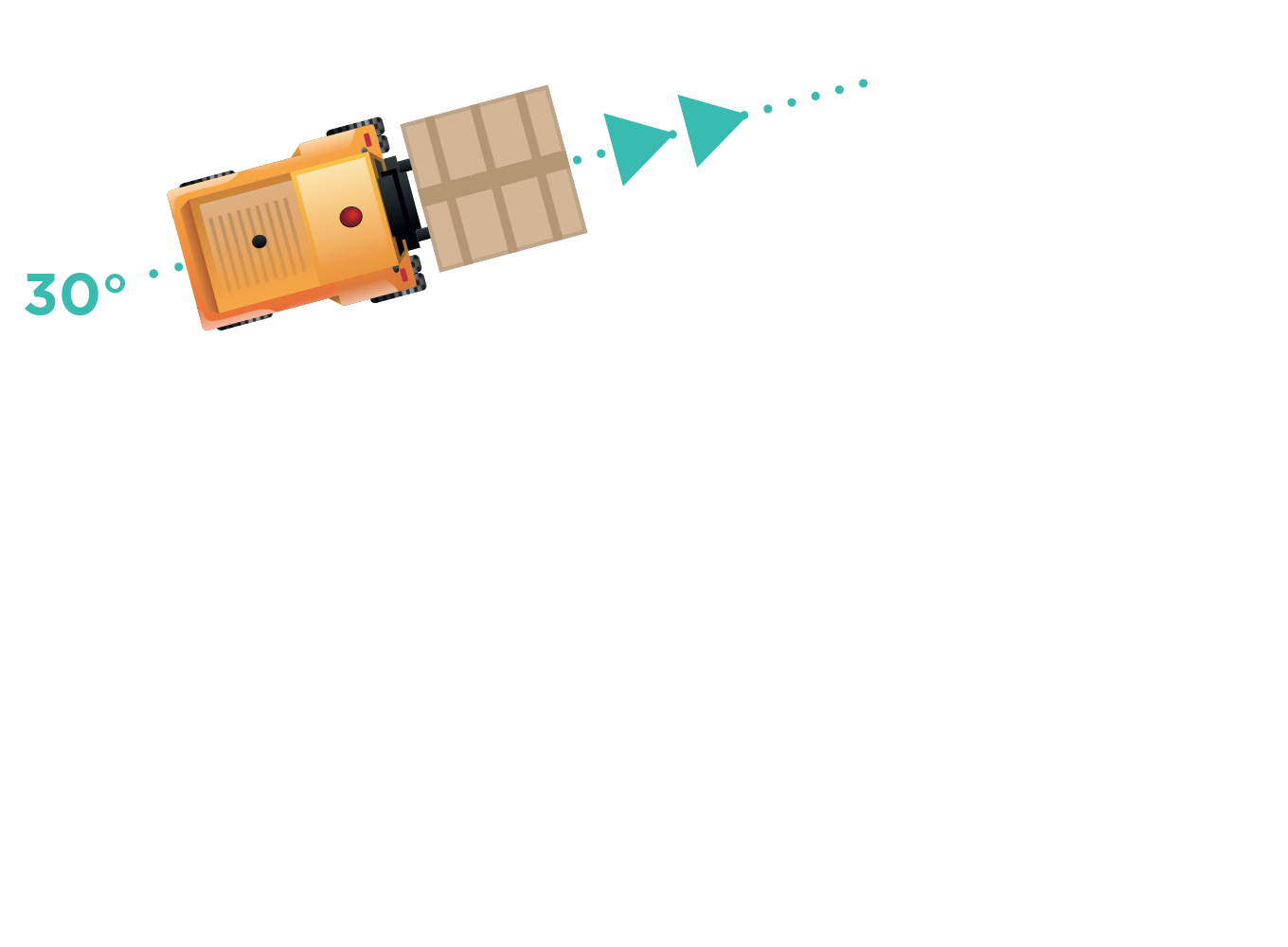

- Possible angle of impact at which a material handling equipment can crash: 15°, 30°, 45° or 90°

The mix of this data helps our Safety Consultant to advise about the best kerb barrier model and its applications. Contact us for more on-line information or free on-site consultancy.

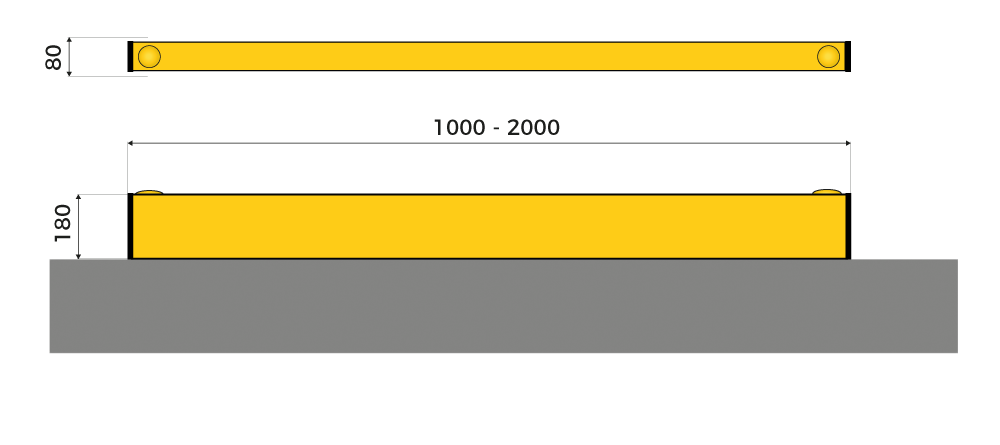

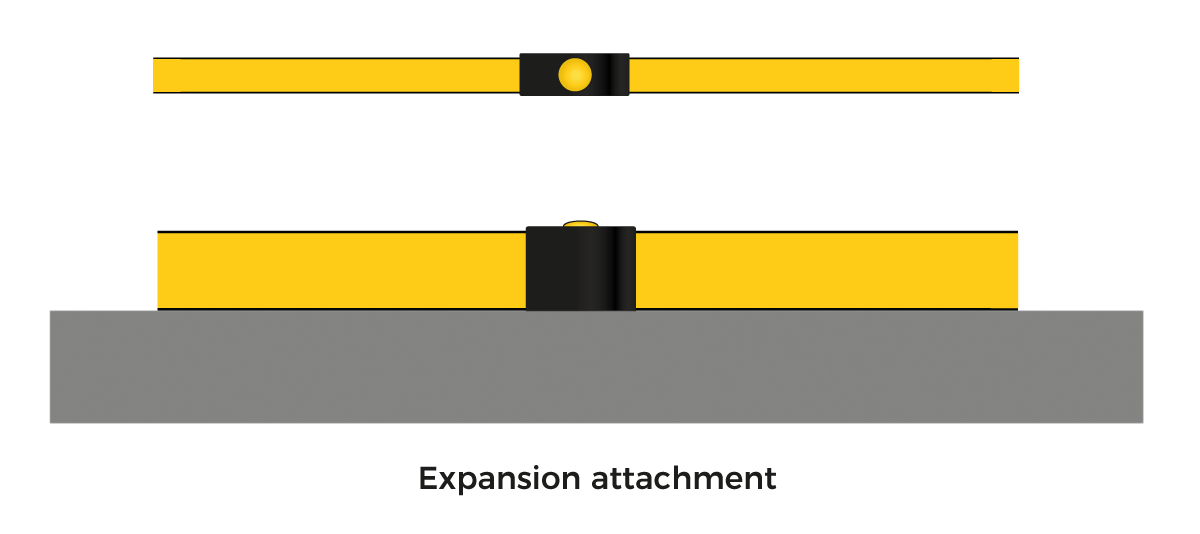

Kerb Barrier Parameters

Depthmm | HeightH - mm |

| Resistancejoules |

| 80 | 180 | 1000-2000 | 7 500 |

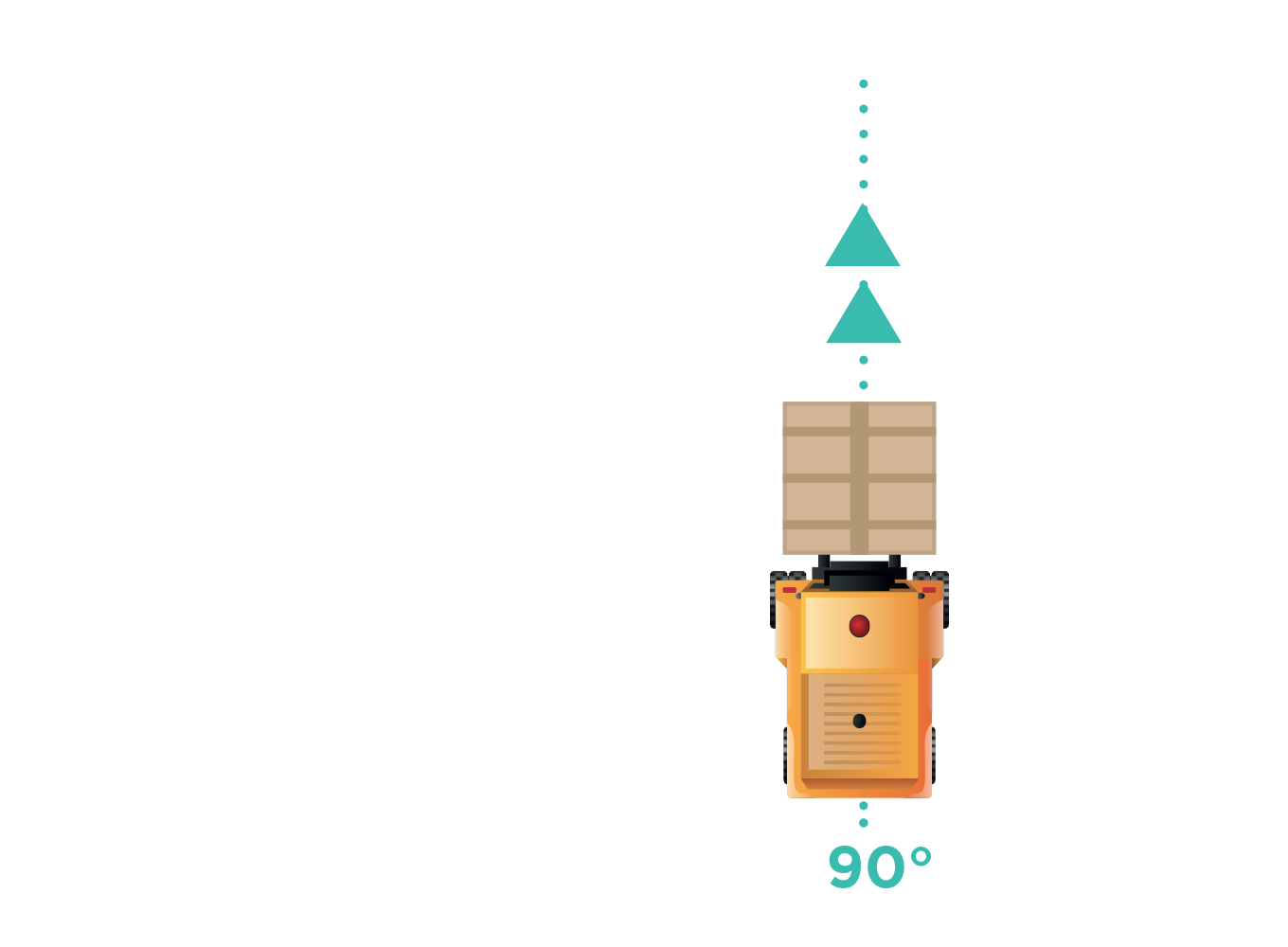

Impact Energy Information

vehicleEnergy: 2 950 J

clickOnTheImageText

| exampleVehicleWeightSpeed | |

|---|---|

| angleApproach | 90° |

| weight | 2 000 kg |

| speed | 6 km/h |

| vehicleEnergy | 2 950 J |

testedToBeCompliantBy BSI – PAS13 testedToBeCompliantAnd UNI 11886.

crashTestsCertified TÜV SÜDcrashTestsCertifiedAfter.

Advantages:

HIGH HYGIENE LEVEL, EASY, QUICK AND INEXPENSIVE MAINTENANCE, NO RUSTING AND PAINTING, COST SAVINGS

Safety, Hygiene, Visibility, Modularity

Kerb Barrier protect